Exterior Photo

This southern California commercial building, houses new R&D facilities for a major multi-national electronic company. Computer equipment housed in a newly constructed research laboratory in the building experienced interference problems.

Interior Photo

The laboratory was located immediately adjacent to the building’s electrical room. Magnetic fields from the electrical equipment caused severe EMI problems with high-performance micro-computer work stations and the development of sensitive electronic components.

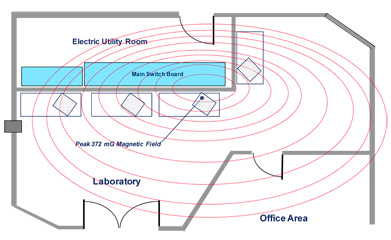

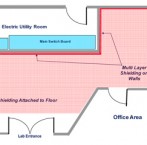

Interior Floor Plan

AC magnetic fields emanating from the adjacent electrical room equipment, created peak values of 372 mG and an average of 30 mG throughout the laboratory area. Researchers requested that the ambient AC magnetic field level in the laboratory be reduced to levels under 2 mG to eliminate potential EMI problems with testing equipment and development of sensitive electronic devices.

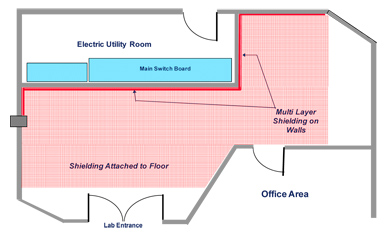

Shielding Plan

FMS designed a robust magnetic field shielding scheme-utilizing multi-layers of shielding material to accomplish extreme reductions of elevated magnetic field levels in the laboratory, to a 2 mG level. The shielding plan required that multiple layers of shielding material be installed on several of the interior walls, and on the floor of the laboratory.

New Interior Shield Photo

The second of three layers of shielding materials installed on the Laboratory common wall with the building’s electrical room.

Interior Shield Photo

This is view of the completed wall and floor shielding installation in the laboratory prior to the restoration of the interior and re-occupancy. Note the small lighting panel in the wall at the far end of the laboratory. The company agreed to limit cost by excluding this area from the shielding – critical equipment would never be placed in this area.

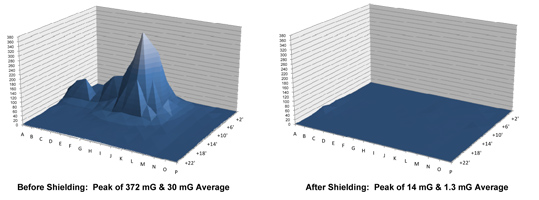

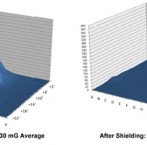

3-D Plots of Magnetic Field Before & After Shielding

These 3-D plots of magnetic fields at one meter from the floor in the laboratory, prior to and after installation of shielding, illustrate the success of the shielding implementation. The average dropped comfortably below 2 mG and the peak next to the lighting panel remained at 14 mG. The laboratory was re-occupied and micro-computers functioned without interference.

Over its 20 years, FMS has successfully completed hundreds of EMI projects which included a diverse range of consulting and mitigation services.

Take a look at a list of the markets we serve »